Podcast: Play in new window | Download

Subscribe: Apple Podcasts | RSS

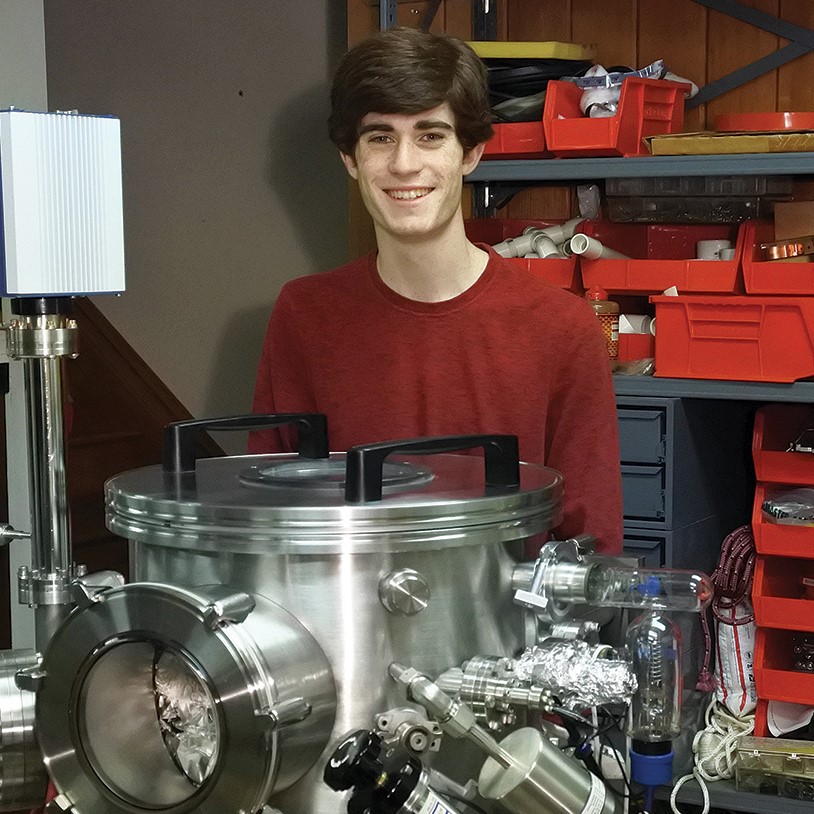

- Welcome Sam Zeloof!

- Sam is graduating high school soon, he’s currently finishing up his senior year.

- Sam started the process of making semiconductors in his garage 1.5 years ago

- 0h 1m 15s

- Sam was inspired by Jeri Ellsworth’s videos

- 0h 2m 45s

- He’ll be attending Carnegie Mellon University in the fall.

- 0h 8m 7s

- Book: Microchip Fabrication by Peter Van Zant

- 0h 10m 23s

- Chemicals are hardest to get

- 0h 12m 21s

- HF in contained in Whink Rust Cleaner

- 0h 12m 40s

- Stump remover

- 0h 12m 54s

- Boric Acid is in roach killer

- 0h 12m 59s

- Sam gives a tour of his lab

- 0h 14m 10s

- Recently finished version of a Dual PMOS differential amplifier!

- 0h 15m 49s

- UPDATE: Sam has published about his recently completed IC

- Added SEM

- 0h 16m 3s

- Wasn’t an option to buy a vapor deposition machine, needed to build

- 0h 17m 43s

- It was PVD, not CVD

- 0h 18m 9s

- Sputtering aluminum

- 0h 18m 59s

- Mean Free Path

- 0h 20m 26s

- Follow along with the slides Sam prepared for a recent showcase of his work in Newark at the Trenton computer fest

- 0h 20m 52s

- Start with wafer, buy off eBay

- 0h 24m 48s

- Check resistivity

- 0h 25m 10s

- Might be obvious, but Sam is not in a clean room

- 0h 27m 13s

- Both Sam and Chris have worked in a Class 100 clean room

- 0h 28m 10s

- UDC internship working on organic LED processes

- 0h 28m 18s

- Oxidizing layer

- 0h 29m 43s

- Photolithography

- 0h 30m 9s

- Silicon gate vs metal gate

- 0h 31m 36s

- Self aligned gate

- 0h 32m 14s

- 4 mask set

- 0h 33m 3s

- What is doping?

- 0h 33m 42s

- Electrons and holes. Talking about holes makes understanding organic semiconductors easier.

- 0h 35m 37s

- Dopants are ppm and ppb

- 0h 37m 55s

- Phosphine and diborane

- 0h 38m 49s

- Adding chemicals and then diffusing

- 0h 41m 14s

- Hardest piece to find is the furnace

- 0h 41m 26s

- HF acid

- 0h 46m 26s

- HF etching of photoresist/oxide

- 0h 49m 26s

- Adhesion promoter HMDS

- 0h 50m 13s

- Spinning on the dopants

- 0h 53m 40s

- Spin coating allows uniform application

- 0h 54m 0s

- Migration of dopants down into the lattice

- 0h 54m 52s

- Get rid of thick oxide

- 0h 57m 12s

- Grow gate oxide

- 0h 57m 25s

- Field oxide is 5000-10000A

- 0h 57m 49s

- Gate oxide is 500 A

- 0h 58m 11s

- Alignment on wafers

- 0h 59m 43s

- Doing photolithography with a projector

- 1h 0m 49s

- Mike Harrison talking about projectors

- 1h 2m 26s

- EUV 13nm

- 1h 2m 39s

- Double Patterning

- 1h 3m 20s

- Scored corner and do y = mx + b

- 1h 6m 30s

- Grateful dead bears

- 1h 8m 25s

- Zeloof Semiconductor

- 1h 9m 57s

- Thinner layers you dilute etchant

- 1h 10m 45s

- Curve tracer

- 1h 12m 1s

- Polished surface is tough for probing

- 1h 12m 48s

- Make a 4 pin pogo tester

- 1h 13m 2s

- 3rd masking step (contact)

- 1h 14m 28s

- Metalization

- 1h 15m 30s

- Everything is shorted

- 1h 15m 36s

- Need to expose the traces that are remaining

- 1h 15m 42s

- How many transistors are you making?

- 1h 16m 33s

- Dual differential amplifier

- 1h 17m 40s

- With larger feature sizes if it looks good, i’ts going to work

- 1h 18m 26s

- CMP

- 1h 19m 35s

- Little Lisa slurry

- 1h 19m 54s

- Silane and CVD isn’t an option

- 1h 21m 6s

- Polysilicon enables more types/more intricate transistos

- 1h 21m 35s

- Max output swing isn’t possible with metal gate

- 1h 22m 17s

- Itsy Chipsy chip service

- 1h 28m 1s

- Design tools – Magic VLSI

- 1h 28m 41s

- Drawing block of transistors

- 1h 29m 17s

- QFlow

- 1h 29m 34s

- Going from Verilog to masks

- 1h 30m 4s

- MOSIS

- 1h 33m 36s

- Wirebonder in process

- 1h 34m 25s

- Former guest Tony Long might have one?

- 1h 34m 54s

- CMU has a new cleanroom and Sam will be allowed to work there as a freshman

- 1h 36m 8s

- Find Sam on YouTube, Twitter and via email

- 1h 37m 46s

This is great! I was going to suggest an interview with Sam after seeing the article about him in the January IEEE Spectrum.

Great interview! Where was doubting Dave? LOL

Just a cautionary note for Sam, wire bonding is somewhat of a black art as much as wafer fab voodoo. I spent 10 years learning and understanding wire bonders as an equipment process engineer.

On the other hand, if Sam wants to setup something with me to learn HOW to wire bond, I can be available, although I am in Houston, Texas. It would be fun, if we could manage a schedule.

Hats off to Sam for tackling and learning this. Kudos to Jeri Ellsworth as a pioneer, as well.