Podcast: Play in new window | Download

Subscribe: Apple Podcasts | RSS

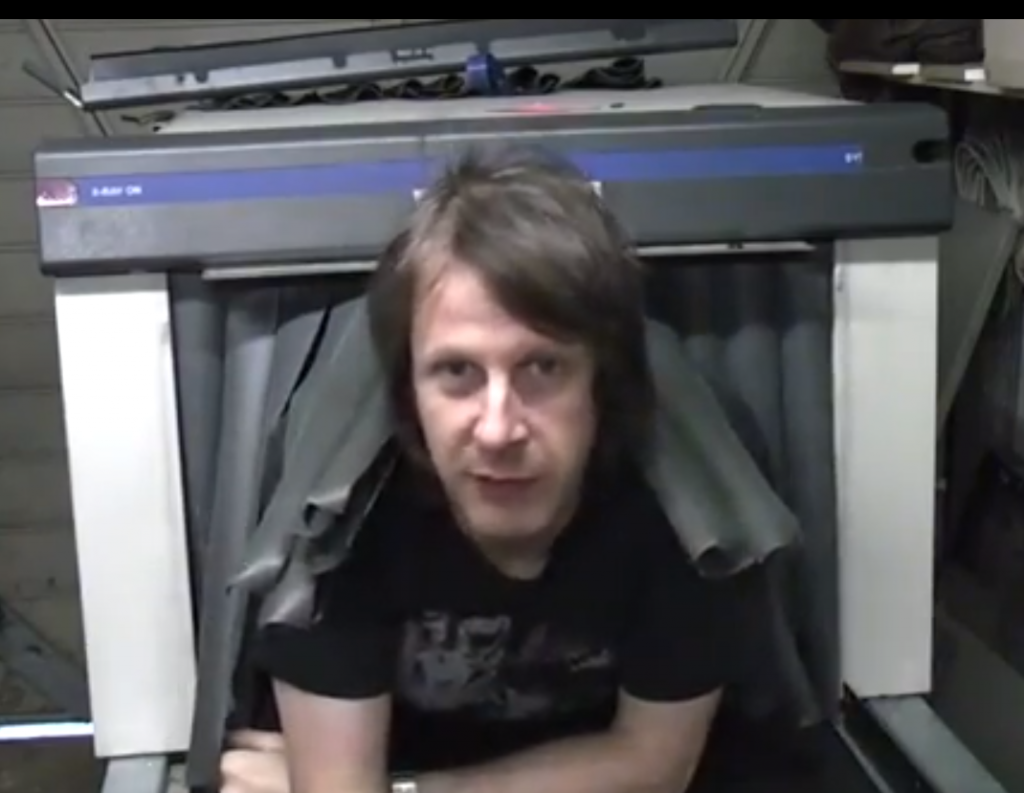

Welcome Mike Harrison of Mike’s Electric Stuff and White Wing Logic!

- Mike’s YouTube channel and videos are likely how many of our listeners know who Mike is.

- Mike has been featured on our show in the past, both as the contributor of the show’s name and sending in photos of his awesome bench!

- He started in a repair department, where he learned to troubleshoot and prank people!

- Later jobs included early IT work with early IBM PCs.

- While at that job, he started designing with the BBC Micro (based on the 6502 CPU) and for the ACORN (now ARM) Archimedes family.

- Many programs Mike writes to interface with lower level stuff is in Visual Basic 6 (now defunct). Chris says there is a downgrade path from .NET.

- He got started with PICs when they were transitioning from Mask ROM parts to One Time Programmable (OTP) parts and a customer needed an alarm system that could output different types of alarms.

- Mike is also a registered consultant with Microchip, which has netted him a job or two in the past.

- He got started with LEDs at Dorkbot in London

- The arts have gotten a boost in London from the Section 106 planning development, which mandates all money spent on building must have some portion go to development (including the Arts).

- Mike’s lab has a pick and place machine in the lab (cost around £8K) which he wrote software to optimize.

- He uses PCAD and does the layout first (!)

- Mike has worked on multiple UFO projects, including one in Gdansk, Poland and one in Seattle for Halo 4

[tube]http://www.youtube.com/watch?v=Uynq2cs1xeU[/tube] - The UK scene, especially the art and architecture scene, is vibrant right now.

- Working with “Technology Will Save Us”, Mike designed the Lumiphone (a soldering project with LEDs and Theramin that costs less than £3) and the Bright Eyes Glasses, which was a Kickstarter campaign.

- Mike is obviously known for his great teardown videos!

[tube]http://www.youtube.com/watch?v=osAKuPGhK3I[/tube] - The baggage X-ray machine took a friend and a van to haul back to his shop…and he broke even on the project!

[tube]http://www.youtube.com/watch?v=KPyE29ABmoA[/tube] - A more recent project has 2106 LEDs and 2106 PICs, one per LED. This new design could have issues if Microchip has supply chain problems, as Steve Sanghi’s letter about lead times seems to suggest.

- Mike thinks a good way to get into art is to make your own. He cited the quadcopter stage show.

- See the silly emails Mike has gotten over the years at his “Muppet alert” page.

- You can find Mike on Twitter at @Mikelectricstuf

Many thanks to Mike for taking the time to speak with us!

Thanks a lot guys for this show.

And yes Mike, come again in a future show 😉

Seems Randy from Higgsville is still following the amp hour and trying to call in. This time he tried calling your guest Mike 🙂

They must have nasty telemarketers in NSW, Dave gets a call at the same time every time he records from home!

But you know, everyone’s trying to keep up with the Joneses.

Great show. I’d really like to hear more from Mike. Perhaps you could try to shedule him on say couple times a year.

Another great show! I found it very interesting that both Mike and I started off (and learned a great deal) in the repair industry. He, in the warranty repairs, and me in the small town TV repair shop.

Me too Alan! My dad was a field repair man for a regional consumer electronics retail company and when I was a kid he used to take me out with him sometimes, explaining what the fault was, how he diagnosed it and repaired it. Before going to uni, I spent a year with him in the same company, repairing faulty stock and shop returns. From those awful cheap nasty radio-cassette units that chewed tapes to big Sony TVs and annoying Philips VHS VCRs.

There’s nothing quite like fault-finding a huge range of products under pressure for getting to really understand electronics and manufacturing.

I can totally identify with wanting to write Turbo Pascal software! In my case it was Turbo C; Superb fast IDE for just hacking stuff together and getting it up and running quickly and efficiently.

I did ever-so-briefly during the show (didn’t want to step on toes), but I too got started in repair, albeit at my first co-op. I friggin’ hated it. I couldn’t stand that they were wasting all my unbelievable knowledge about voltage dividers using two 10K resistors and a 5V source! I mean C’MON people, I had two years of coursework, some of it even about electronics!

In the mean time, I finally learned how to properly solder, how to troubleshoot and was put in my place (thank goodness). One of those experiences in my life that I now look back on with perspective and smile. I’m sure I’d be an even crappier engineer without it!

My first full time job was as a repair tech fixing CCTV and slow scan TV gear when I was 17.

You do learn a lot!

Cool! thanks for answering my question

I enjoyed this episode and #133 very much because of the insights into the work of Mike and Ron.

The Stories and shared insights of your guests are always a great addition.

Not every episode should have a guest because the mixture

of episodes tih and without guests is just right.

Thank you for what you did and do.

Another great show!

Love the photos of Mike’s bench, truly Awesome!!!

The pill camera blogg is awesome 🙂

Really enjoyed hearing Mike and all his stories etc. I hope he’ll get another spot on The Amp Hour as I could listen to him all day.

Thanks guys

It’s sooo weird to hear Mike laugh…